Back

Share

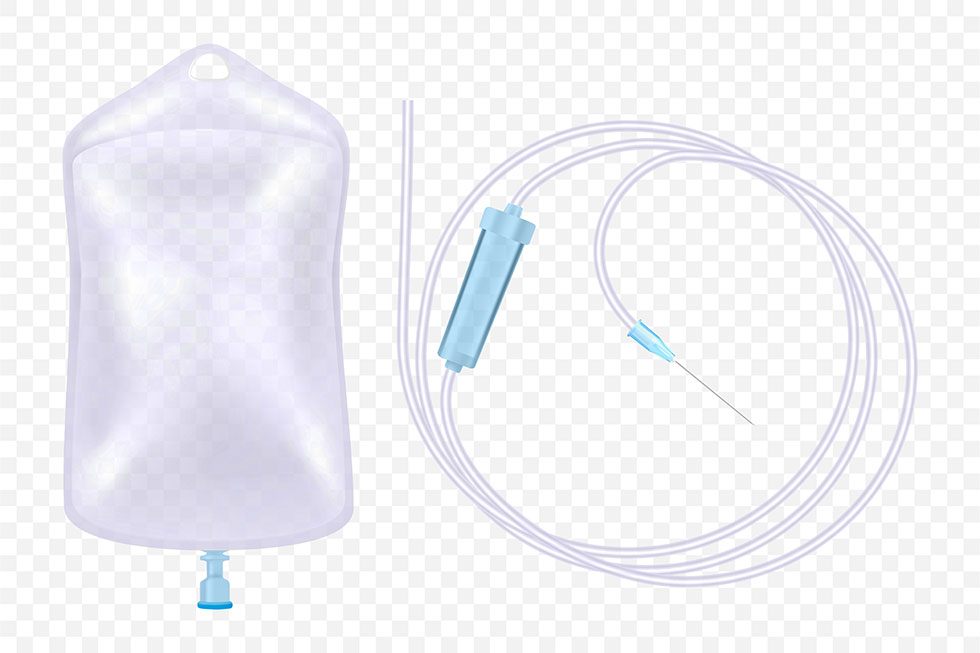

Medical Tubing and IV Sets Utilizing TPE Compounds

Medical tubing and IV sets play a vital role in modern healthcare by facilitating the safe and efficient delivery of medication and fluids to patients. As a critical component of medical devices, these products are subject to stringent regulatory requirements and must meet the highest standards of quality and safety.

In contrast to other types of instruments, medical tubing and IV sets are designed specifically for medical applications and are subject to rigorous certification and regulatory standards. This ensures that the materials and specifications used in the manufacturing process meet the strict requirements necessary to maintain the health and well-being of patients.

The use of inappropriate materials or substandard manufacturing processes in medical tubing and IV sets can result in serious health risks for patients. As such, manufacturers must adhere to strict guidelines and regulations to ensure the safety and effectiveness of these critical medical devices. By utilizing high-quality materials and adhering to industry best practices, manufacturers can produce medical tubing and IV sets that meet the unique demands of the healthcare industry and improve patient outcomes.

Enhancing the Quality and Performance of Disposable Medical-Grade Tubing through the Use of Thermoplastic Elastomer (TPE) Compounds

The advent of Everlon TPE compounds has revolutionized the field of disposable medical-grade tubing for medical applications. These innovative TPE compounds offer a host of benefits over traditional tubing, including superior clarity, smoother surfaces, reduced leachables, and lower protein binding. Moreover, they offer exceptional resistance to repeated compression, ensuring consistent performance and freedom from kinking.

In addition to their enhanced performance characteristics, TPE medical tubing also offers increased resilience and durability, making it an ideal choice for demanding medical applications. The exceptional mechanical properties of these materials ensure that they can withstand the rigors of use in medical settings, providing reliable and consistent performance throughout their lifespan.

Overall, the use of TPE compounds for medical tubing represents a significant advancement in the field of medical device manufacturing, offering superior performance and reliability for healthcare professionals and their patients. As such, they have become the material of choice for a wide range of medical applications, delivering exceptional quality and performance in even the most demanding environments. The key benefits of using TPE compounds for medical tubing include:

-

Optimal clarity, providing improved visibility and ease of use in medical applications

-

Lightweight, tough, and flexible properties that make TPE compounds similar to rubber

-

Kink-free, ensuring smooth and uninterrupted flow of gases and liquids through the tubing

-

Ability to handle a wide variety of gases and liquids, making it a versatile solution for medical applications

-

Wide range of hardness options available, allowing for customization to meet specific application requirements

-

Ability to pass a wide range of pressure testing, making it suitable for use in extended medical tube applications

-

Complies with FDA and USP Class VI requirements, ensuring that TPE materials are made with non-toxic ingredients that meet the highest safety standards for medical use.

Utilizing Thermoplastic Elastomer (TPE) Compounds to Develop a Comprehensive Range of IV Connectors, Sets, and Consumables

The use of innovative TPE materials has been instrumental in advancing the safety and efficacy of IV therapy. These materials offer a range of clinical benefits, including infection control properties and a broad portfolio of IV sets that can be tailored to meet a variety of clinical needs.

With the help of TPE compounds, healthcare professionals now have access to the broadest offering of IV sets on the market. These sets have been designed to deliver optimal performance, providing reliable and consistent results across a range of clinical applications. Whether used for short-term or long-term infusion therapy, TPE compounds offer a safe and effective solution for delivering critical medications and fluids to patients.

Moreover, TPE compounds are ideal for use in connectors and other consumables, offering exceptional durability, flexibility, and biocompatibility. By leveraging these advanced materials, healthcare providers can ensure that their patients receive the highest standard of care, with a reduced risk of complications or adverse events. TPE compounds offer a wide range of applications in the medical industry, including:

-

IV sets:

TPE compounds can be used to create a broad portfolio of IV sets, which are critical in delivering medications and fluids to patients. The enhanced performance and durability of TPE materials ensure consistent and reliable results in clinical applications, while tailored designs can be customized to meet specific clinical needs. -

Catheters:

TPE compounds are ideal for use in catheters, offering exceptional biocompatibility and non-toxicity. TPE materials can be customized to meet specific clinical needs, improving patient outcomes and reducing the risk of complications associated with catheter use. -

Respiratory equipment:

TPE compounds can be used to create a range of respiratory equipment, including masks, tubing, and other components. The flexibility and durability of TPE materials ensure optimal performance in these critical medical applications. -

Connectors and extension sets:

TPE compounds offer exceptional resistance to kinking, making them an ideal choice for use in connectors and extension sets. TPE materials are flexible and durable, ensuring smooth and uninterrupted flow of fluids and gases through medical devices. -

Biopharmaceutical laboratory equipment and devices:

TPE compounds are used in the development of biopharmaceutical laboratory equipment and devices. These materials offer exceptional biocompatibility and non-toxicity, ensuring that laboratory equipment is safe for use in medical applications.

Expert Support Services from Everlon for Your Medical Device Manufacturing Needs

Everlon provides expert support services to meet your specific needs in medical device manufacturing. Our key services include:

-

Customized TPE Compounds:

We offer customized TPE compounds that are tailored to your specific requirements, ensuring optimal performance in your medical applications. -

Technical Advice:

Our team of experts is available to provide technical advice and support for unique applications, helping you to achieve optimal results in your medical device manufacturing process. -

Processing Support:

We provide support in simulations with extrusion, blowing, and casting processing in our cleanroom workshop (Class 100,000), ensuring the highest levels of quality control and compliance. -

Comprehensive Laboratory Equipment and Testing Options:

Our laboratory equipment and testing options are comprehensive, ensuring that your TPE materials meet the highest standards of quality, biocompatibility, and safety. -

Recyclable TPE Materials:

Our TPE materials are recyclable at any step, reducing waste and supporting sustainable manufacturing practices. -

Compliance with USP Class VI Certification:

Our TPE formulations comply with USP Class VI certification, ensuring that your medical devices meet the highest standards of biocompatibility and safety.